Hi Guys,

Sorry for the delay, going through a house remodel and I have just had no time to myself.

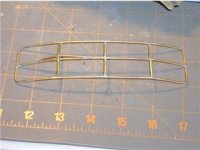

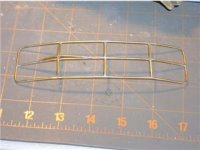

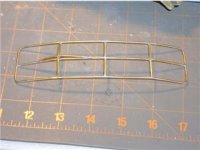

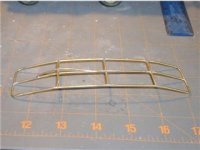

Here's some initial pics, The array is made of brass rod that I sildered together, the support legs are brass tubing and the push assambly on the front is Evergreen plastic building materials. all are available at a good size hobby shop. I use a piece of tile to solder on and a soldering gun as opposed to an iron as it generates a faster and hotter heat. I use rosen core solder, .032 dia. the rosen cleans the metal during the soldering process for a quick even solder joint. Any excess I just filed off.

Sorry for the delay, going through a house remodel and I have just had no time to myself.

Here's some initial pics, The array is made of brass rod that I sildered together, the support legs are brass tubing and the push assambly on the front is Evergreen plastic building materials. all are available at a good size hobby shop. I use a piece of tile to solder on and a soldering gun as opposed to an iron as it generates a faster and hotter heat. I use rosen core solder, .032 dia. the rosen cleans the metal during the soldering process for a quick even solder joint. Any excess I just filed off.