Wolfgang_UK

Staff Sergeant

- Joined

- Dec 5, 2009

- Messages

- 836

Hi Brad,

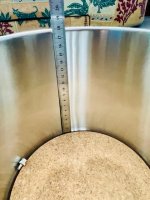

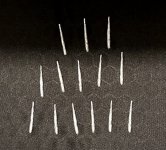

Hi Brad,One casualty out of eight is more than ok, it is all down to my selfinflicted "human error" anyway. Most important is what industry does call PROCESS SECURITY. This term simply stands for being able to succesfully and repetitively manufacture qualitywise a "Class A" article within a rather small drop out tolerance throughout the entire production circle. Haveing said that anybody will be quick in finding out that Casting with resins is much more demanding than one might think. Possibilities to produce faulty castings are plentyfull and resins sometimes seem even to ignore the laws of physics - not to speak of the mold-maker and caster.

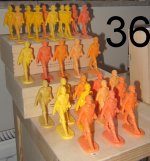

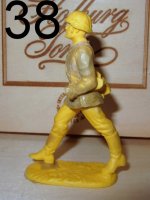

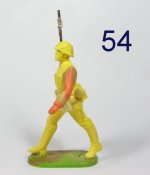

Some colour now. Picture of a group of officers useing different colours to dye the resin, castings not cleaned up yet.

Regards

Wolfgang