fishead19690

Command Sergeant Major

- Joined

- Nov 3, 2005

- Messages

- 2,555

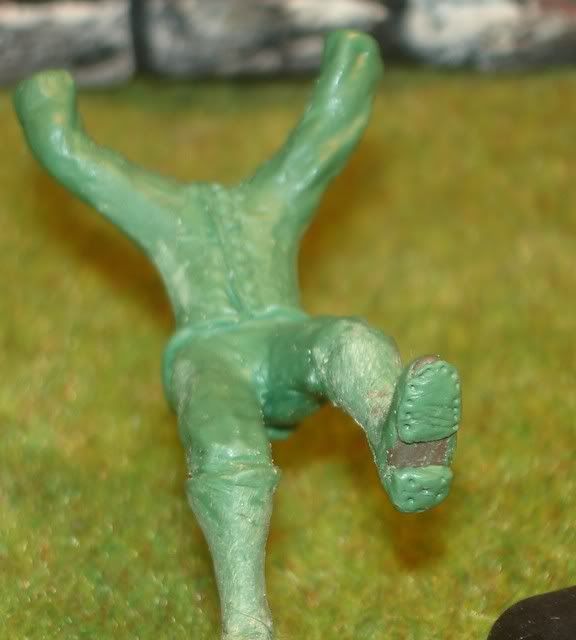

Nice job. Once you start making rubber molds the pose possibilities are almost limitless, plus you can just cut the vent out of the rubber instead of casting it. Two part plastics are unpredictable. I have a mold for a two piece set and I poured the plastic in both cavities. One turned out perfectly, the other was a gooey mess that never cured and it took forever to get the gunk out of my mold.

That,s what happens when you eye out your one to one instead of getting a good solid 1 to 1 mix with some type of measureing cup.

I,ve done that before also where I had the mix a bit off and it took forever to cure.

If you know which one of 2 parts is the hardner you can play a bit with how the plastic will come out.

To much hardner and you get a real hard brittle plastic, cut it back a bit and you,ll get a more softer flexable, but be carfull doing this or you,ll end up with a mess in your mold that won,t cure.

If that happens and you have that sticky mess in there you could pour a bit more hardner onto it then let it cure and pull it out to save the mold.

The more hardner the quicker it,ll kick also and if not enough it,ll take forever! Tempatures will effect the cure time also.

Its best to just stick to mixing this stuff right on 1 to 1 though.