sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

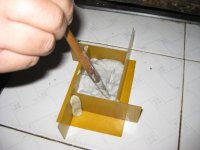

he first part of the cutting toy soldiers.When we have completed the work after the sculpture toy soldiers, we must be cut into several parts, so that we can work on the casting parts.

Cutting as much as possible the gap along the cut of clothes. This will guarantee that the casting of the parts can be a natural connection. Toy soldiers will not be any major body surface cracks.

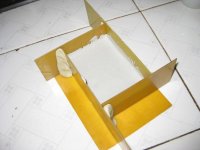

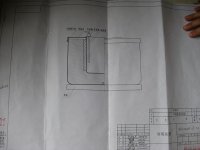

Cutting work must be carried out step by step. First of all, cut the hands holding weapons or items, if possible, should consider holding hands and the hands of cutting items together. The second part is cut off two arms, the following chart:

Cutting as much as possible the gap along the cut of clothes. This will guarantee that the casting of the parts can be a natural connection. Toy soldiers will not be any major body surface cracks.

Cutting work must be carried out step by step. First of all, cut the hands holding weapons or items, if possible, should consider holding hands and the hands of cutting items together. The second part is cut off two arms, the following chart: