You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Step by step, casting the toy soldiers with me (1 Viewer)

- Thread starter sunyi

- Start date

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

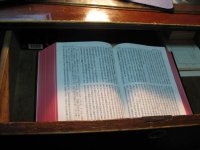

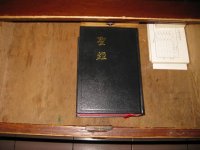

This is my Bible, from the left side open, vertical version of the ancient Chinese, the seventeenth century translated into Chinese. Your looks may be related to the Bible, there are many different, but faith in God is of all human.

Attachments

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

Hello sunyi,

Thank you very much for sharing your work.

You have gone into great detail with your pictures.

Perhaps, you can show us some of your painted figures.

Kind Regards, Raymond.

Dear Raymond:

The new mold is being dried, I plan to start casting next week, and then began to build up, painting. And the content of the painting I plan to "Painting" to open a thread.

I also plan to "Sculpting" section to open a thread for how to sculpture a toy soldier. Hope that we can develop toy soldiers in own home .

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

Hot weather last week, I did making molds when the system was not wearing masks, inadvertently inhaling gypsum, resulting in bronchial inflammation, has been a fever and cough. Failed to cast a timely manner. In this apology to you.

Draw your attention to: Do you have to wear a mask when you making molds.

Casting parts out there should be a post-processing, using a knife to cut out edges, and then from 502 adhesive. Do later in the process.

Assembly and coating color work will be "Painting" section set up another thread demo.

End goodbye

sunyi 孙屹

Draw your attention to: Do you have to wear a mask when you making molds.

Casting parts out there should be a post-processing, using a knife to cut out edges, and then from 502 adhesive. Do later in the process.

Assembly and coating color work will be "Painting" section set up another thread demo.

End goodbye

sunyi 孙屹

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

This is another LAMA, due to casting the liquid metal in the process temperature is too high, there are some parts the surface shrinkage. Casting large parts due to temperature should be controlled at 190 ~ 200 degrees Celsius.

Attachments

sunyi

Private 2

- Joined

- Feb 12, 2008

- Messages

- 104

So that's how it's done......WOW......Good stuff.....Thanks for the lesson......

Regards,

Canucks

A few weeks, I will set up another thread of how to sculpture, stresses how the human-shaped sculpture.

kilted vampire

Lieutenant Colonel

- Joined

- Mar 2, 2006

- Messages

- 7,900

Sunyi thank you for the great tutorial

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)