Mold Sizes

Scott, the basic block, mold #40, from Hirst arts is $34.

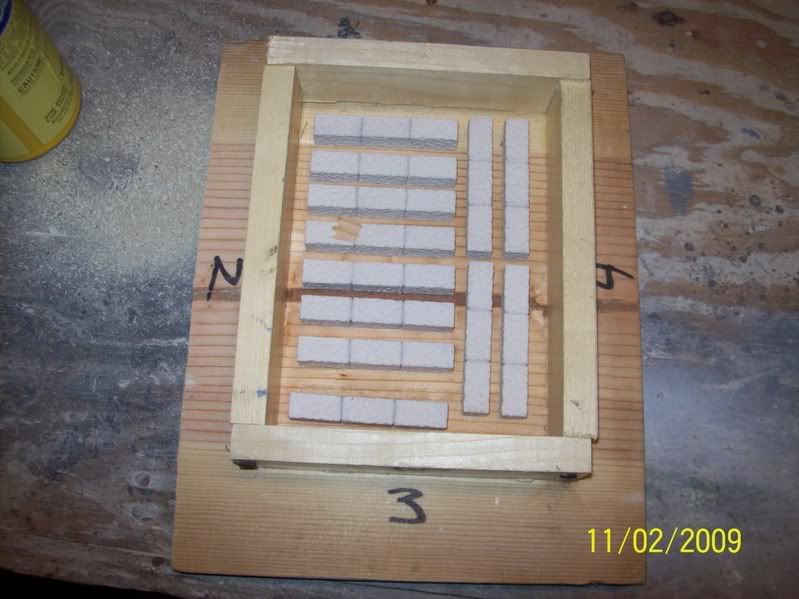

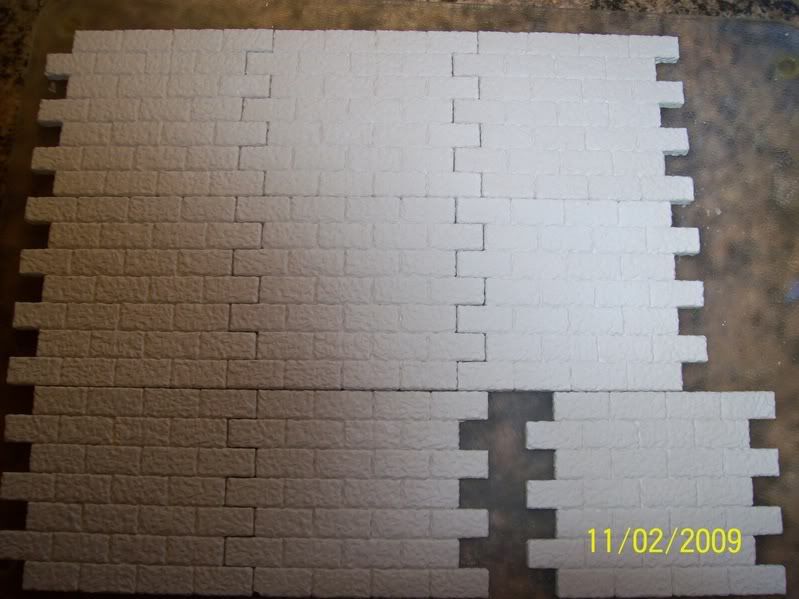

I have a picture of it here. It’s the blue mold. It produces 20 bricks per cast.

It produces 5-½” long blocks

2-¾” long blocks

10-1” long blocks

1-2” long block

2-3” long blocks

All the blocks are ½” wide and ½“ deep.

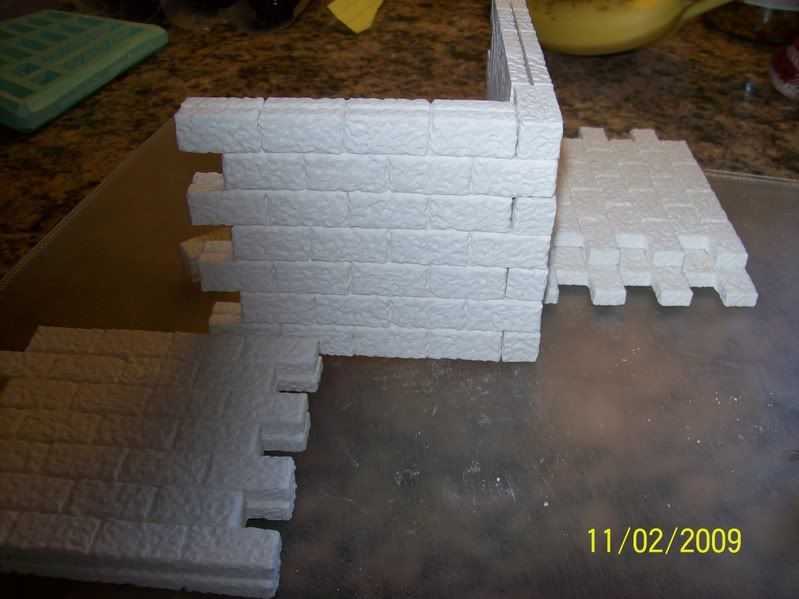

One of my 4 towers (the tallest) is 19”’s tall and 7”s deep x 7”’s wide.

In comparison the,

JG Ancient City Gates towers are 10 ½”s tall and 3 ½”s deep x 3”s wide.

My towers dwarf the JG towers. They are over twice as big.

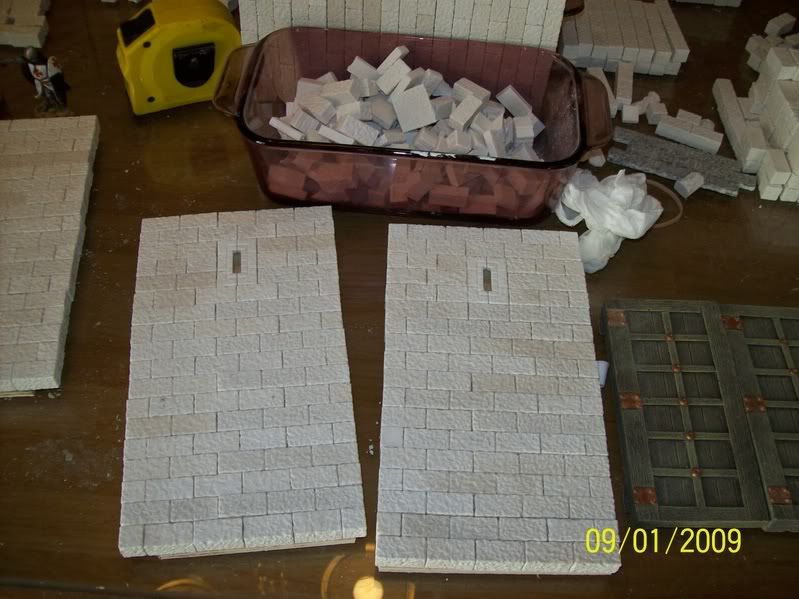

To build my tallest tower, takes 1,064-1” blocks (if my math is right), so you can see, I was molding like a mad man.

Each tower layer has 7-1” blocks wide and 7-1” blocks deep = 28 blocks per square.

Multiply that by 38 square rows high and you get 1,064 blocks to make that tower (if my math is right).

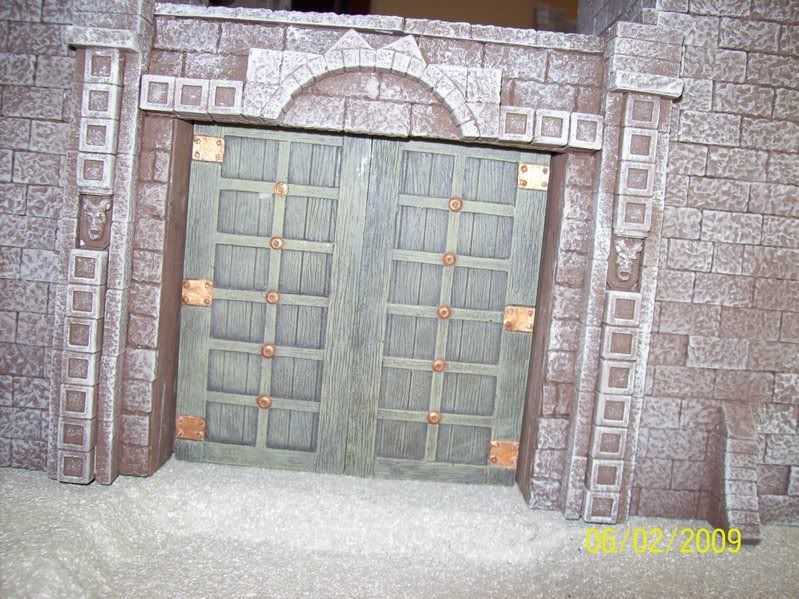

Excluding a few blocks for arrow slits, crenels (the open spaces between the merlons of a wall or tower battlement), merlons (the solid part of the wall or tower battlement), windows, doors etc…

It seems insurmountable to make 1,064 blocks per tower when I add it up, but the blocks seem to multiply geometrically and are really fun to make.

I made my own rubber silicone mold that produces 12-3” bricks to speed up the process (the one in purple). I began mass producing them. It was simple and works great. It really helped produce bricks like an assembly line.

My purple mold was made with a product called OOMOO 25 silicone rubber. It was very easy to make and I’ll show you later how to do it. You can cast almost anything you want in Hydrostone TB from the rubber molds you make. You can make molds of almost anything you want.

This Hirst Arts is really cool and you used it well. I've seen their website before but never tried it because of the scale issue but you've solved that problem.

This Hirst Arts is really cool and you used it well. I've seen their website before but never tried it because of the scale issue but you've solved that problem.