Moe, thank you. That is very kind of you to say all that. My verbosity is good for something. You are quite accurate when you sat that KotS collectors are few but passionate. Your recent poll about JJD aircraft kind of proved it. There were 14 responses to that poll and I'm sure they are the same collectors that respond on this thread. The passion shows in the number of views and the number of posts that such a relatively small number of collectors have managed to put up here (though I suspect there must be many silent collectors of this series). This thread has over 87k views and 1000 posts. Quite remarkable. It proves that the perceived romance and innocence of the first air war still has some fans in this day of jets. It is also proof that the wonderful models from JJD (and all that go with them) have a dedicated and loyal following, with an insatiable appetite for all things with wooden wings.^&grin -- AlHi Al,

Thank you so much for the update. That's the best intel we've had regarding JJ model airplanes in quite a while .

I noticed that the KotS thread has hit one-hundred pages. So, how about that!Who'd have thought that it'd have proved to be so valuable a resource for collectors when MCKENNA77 started it four-and-a-half years ago?

Now, let me thrust an opinion on you and our other readers...

Al, it's been you who's kept this thread afloat. KotS collectors may be few in number, but they're passionate and dedicated to the range. No one that I'm aware of has done more to spur their interest in Jenkins' little replicas than yourself. You are our "most valuable player," and the rest of us will be forever in your debt for fleshing-out the nuances of these models and figure sets.

A heartfelt thanks and best wishes for the future,

-Moe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knights of the Sky (1 Viewer)

- Thread starter MCKENNA77

- Start date

chalklands

Sergeant First Class

- Joined

- Aug 2, 2007

- Messages

- 1,198

Hi,

Just received the Eindecker (ACE-23), it is a superb model. VERY pleased with it!

Pete

Just received the Eindecker (ACE-23), it is a superb model. VERY pleased with it!

Pete

mileshumphreys

Private 2

- Joined

- Jun 27, 2014

- Messages

- 51

And so did I and I am thrilled with it..stunning!!Hi,

Just received the Eindecker (ACE-23), it is a superb model. VERY pleased with it!

Pete

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

How about the Morane-Saulnier N? Any opinions or reviews? Anyone? :smile2:

Hi Al,

The MS is just arriving at USA dealers. TF, has it, I believe. I doubt that collectors over here will receive one before next week.

-Moe

Terp152

Major

- Joined

- Sep 17, 2009

- Messages

- 6,737

Hi Al,

The MS is just arriving at USA dealers. TF, has it, I believe. I doubt that collectors over here will receive one before next week.

-Moe

Should have mine next week sometime. Chris

cantinetozzo

First Sergeant

- Joined

- Oct 26, 2008

- Messages

- 1,362

Quite like the two new generic pilots that John has announced. Really impressed with the detail on the German's uniform and the relaxed, leaning attitude of the French pilot, but as was mentioned in another thread, he needs an aeroplane to lean against. A Spad or Nieuport in appropriate French roundels would do nicely, thank you.:wink2: -- Al

Or needs to lean on another pilot!XD

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

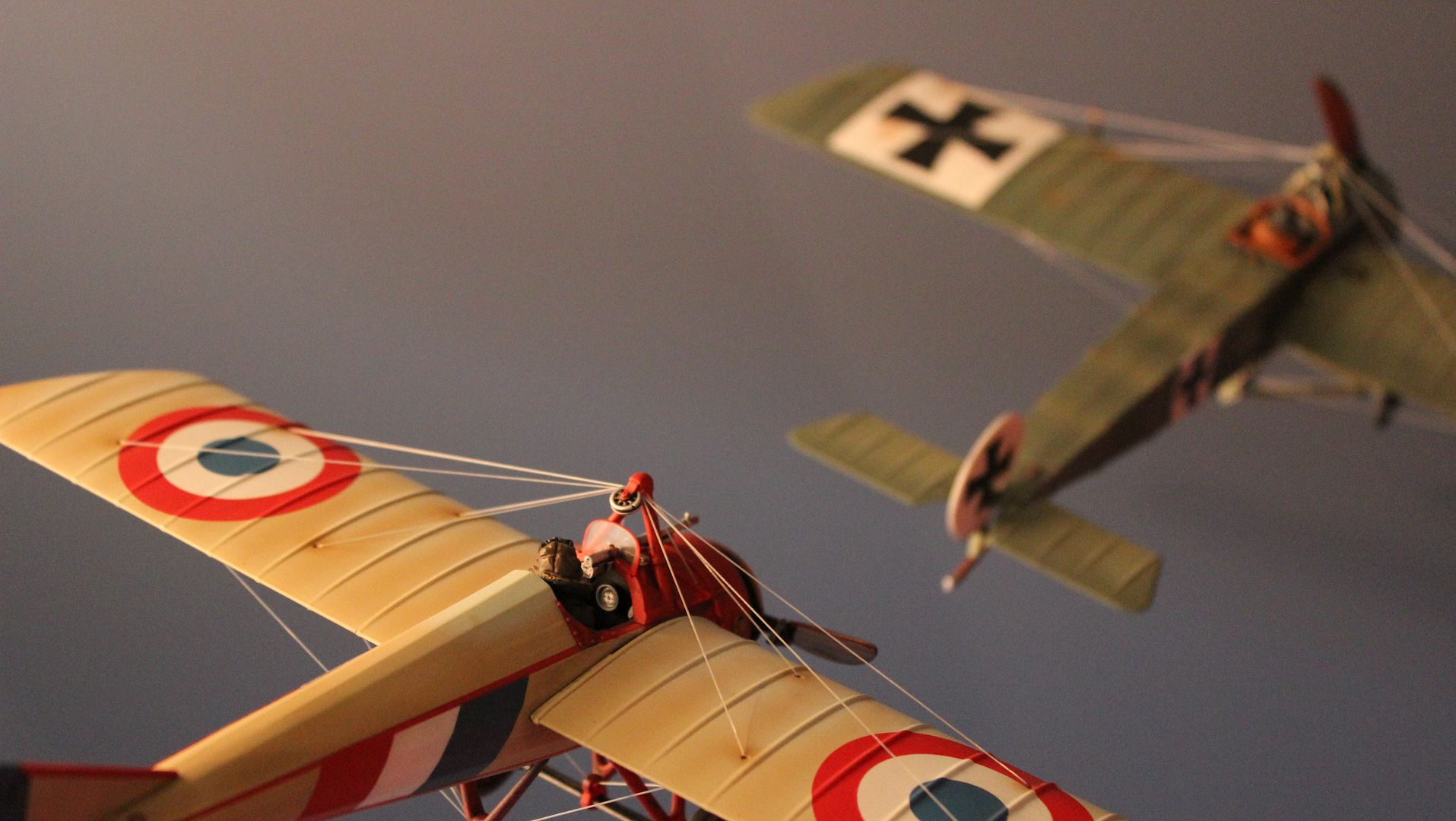

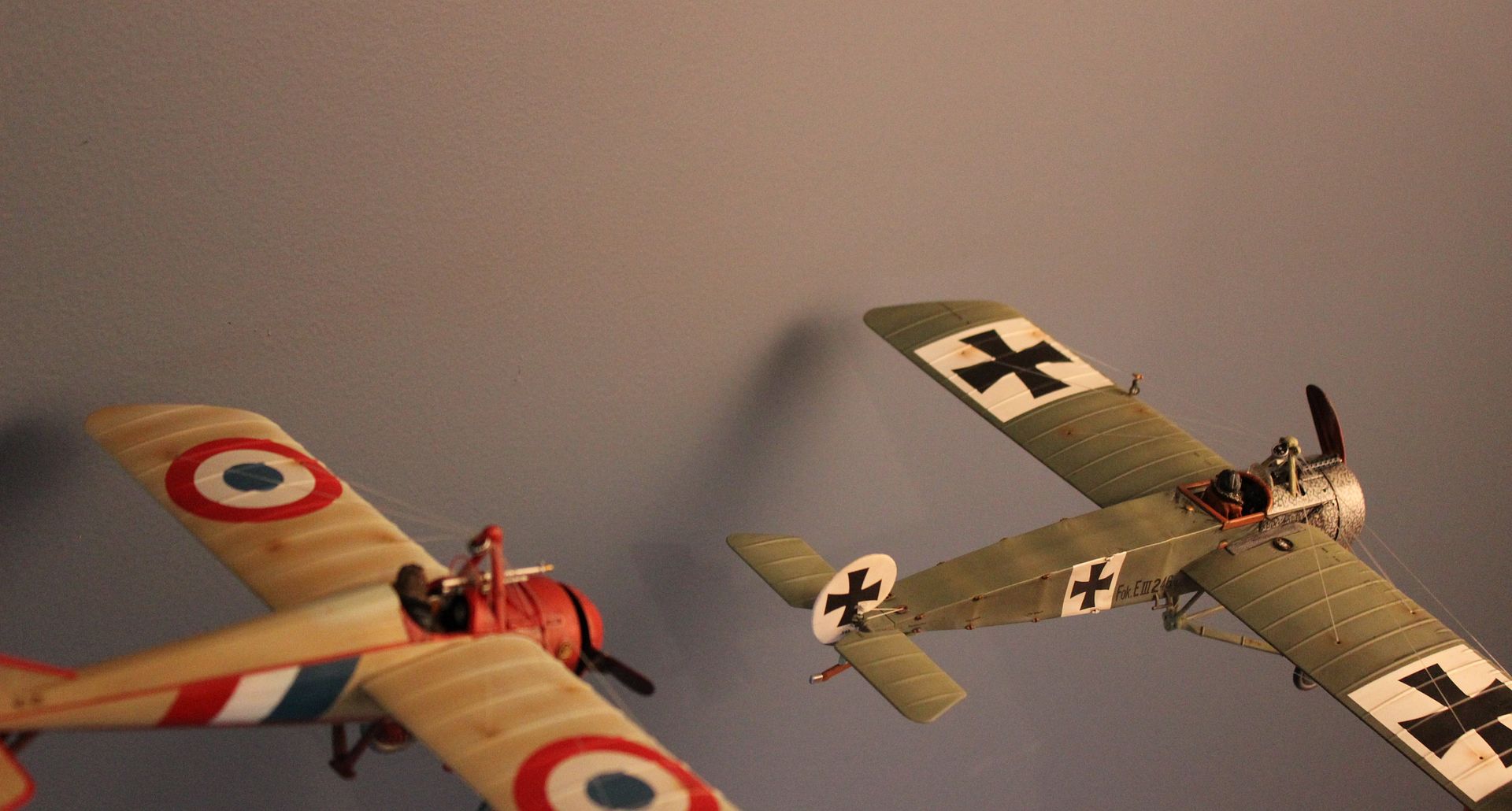

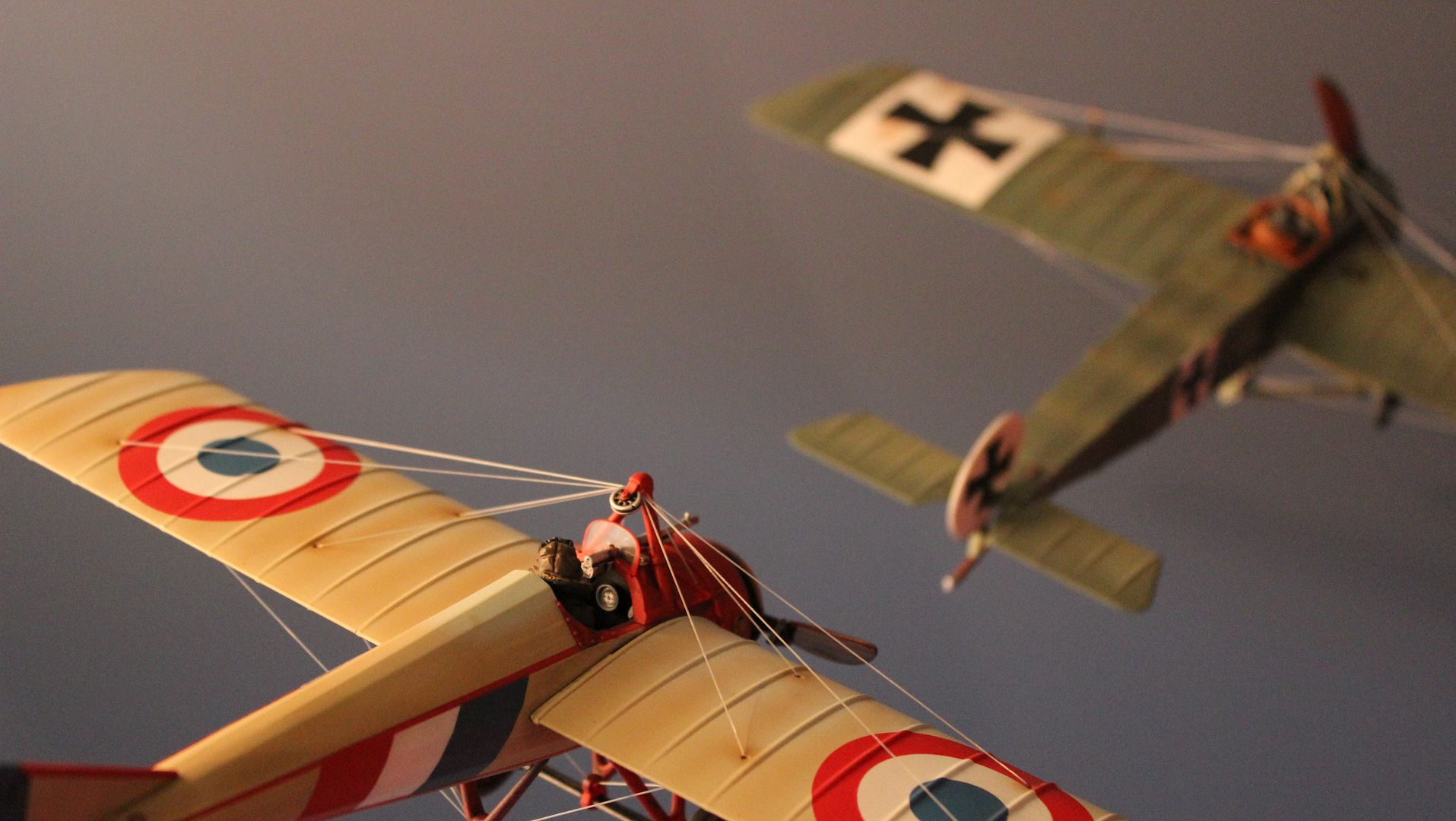

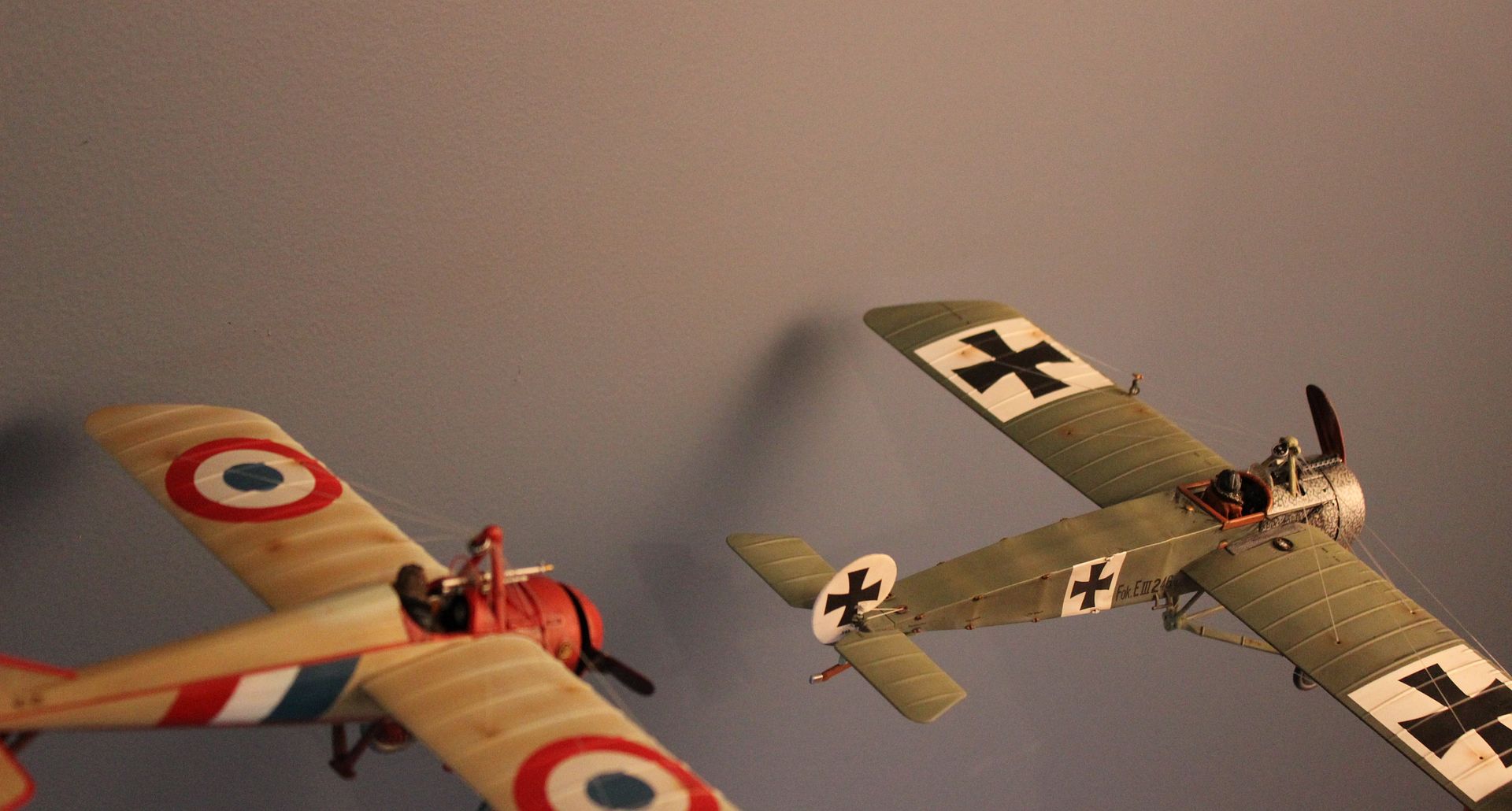

ACE-18(S)

Morane-Saulnier Type N

Escadrile MS 394, 1915

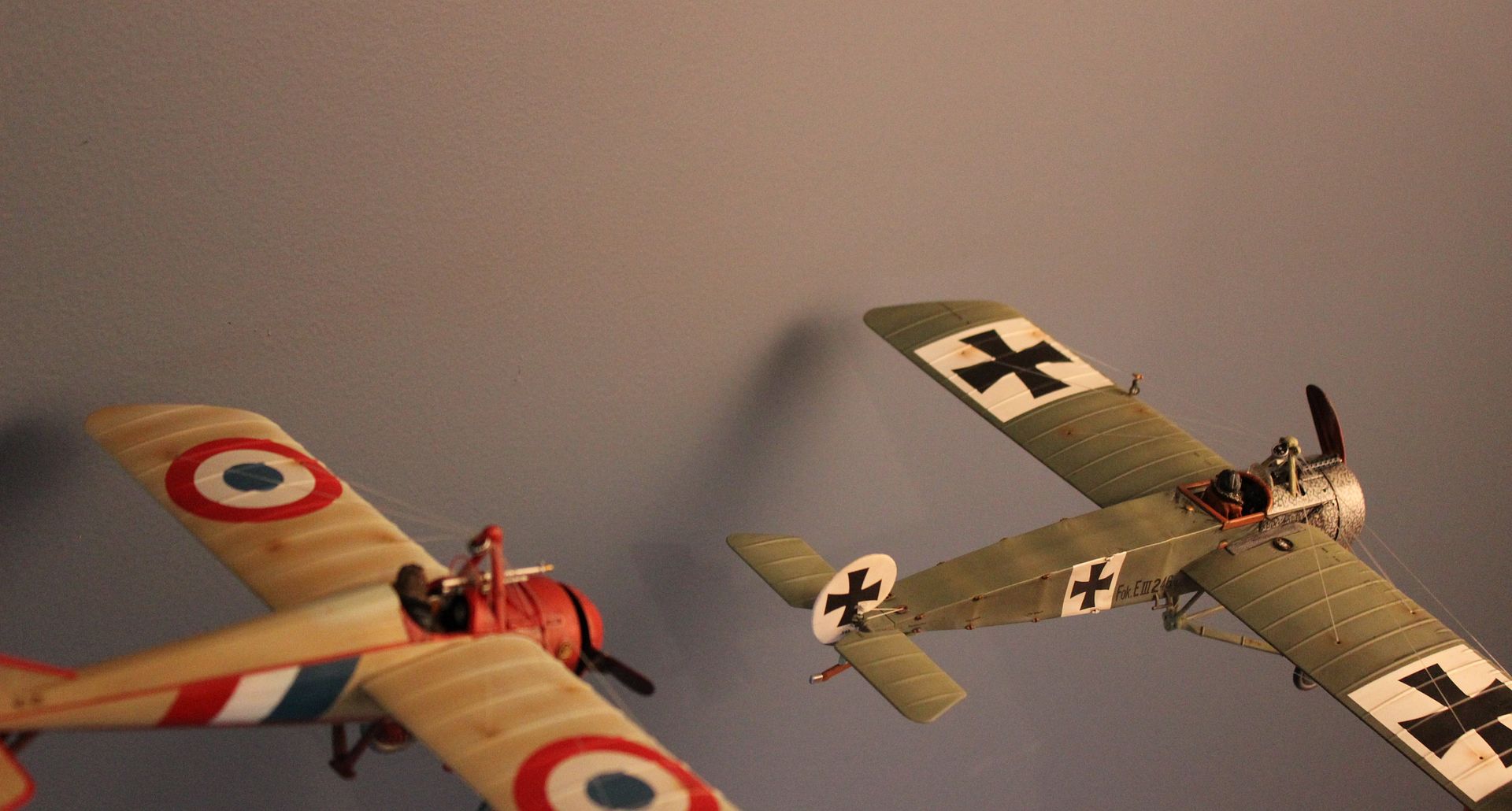

The new MS monoplane arrived today, so I thought that I'd post some pics of it. Arriving so closely on the heals of the somewhat similar Immelmann Fokker E.III, I'm going to upload the images and then allow the readers to fill in the commentary on this one. I will post a few brief thoughts at the end of the pics. First, the walkaround:

Continued Below...

Morane-Saulnier Type N

Escadrile MS 394, 1915

The new MS monoplane arrived today, so I thought that I'd post some pics of it. Arriving so closely on the heals of the somewhat similar Immelmann Fokker E.III, I'm going to upload the images and then allow the readers to fill in the commentary on this one. I will post a few brief thoughts at the end of the pics. First, the walkaround:

Continued Below...

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

Now for some detail pics:

So, there you have it. While the MS-N is similar to Jenkins' recently released Eindecker, it's in no way a simple "knock off" the of latter. Rather, I see JJD taking the methods that it developed for the E.III and putting them to work on its Morane Saulnier replica. In terms of quality, this one, IMO, rivals any model airplane that Jenkins has ever produced. While somewhat smaller than the E.III, it's a very tight, finely finished model. At about $185.00, it's also a heck of a bargain, being fifty dollars less expensive than the Eindecker. JJ has set an awfully high standard with these last two releases. The only question now is, can they keep it up?

Hope you enjoyed the pics!

-Moe

So, there you have it. While the MS-N is similar to Jenkins' recently released Eindecker, it's in no way a simple "knock off" the of latter. Rather, I see JJD taking the methods that it developed for the E.III and putting them to work on its Morane Saulnier replica. In terms of quality, this one, IMO, rivals any model airplane that Jenkins has ever produced. While somewhat smaller than the E.III, it's a very tight, finely finished model. At about $185.00, it's also a heck of a bargain, being fifty dollars less expensive than the Eindecker. JJ has set an awfully high standard with these last two releases. The only question now is, can they keep it up?

Hope you enjoyed the pics!

-Moe

Moe, spectacular photos. Thanks very much for posting them. The downside is that I was hoping I might not like this release and might be able to pass on this one. I was wrong. It is a beautiful little aircraft and looks, as you say, to be the equal, if not the better of the outstanding Eindecker. I will have to have it. It is highly detailed and the colors and markings are very attractive. I really love the detail of the 'brass' MS logo on the cowling side. Guess I'll just have to cut back elsewhere.:rolleyes2: John, and I don't know how he does it, is just getting better and better. -- Al

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

Moe, spectacular photos. Thanks very much for posting them. The downside is that I was hoping I might not like this release and might be able to pass on this one. I was wrong. It is a beautiful little aircraft and looks, as you say, to be the equal, if not the better of the outstanding Eindecker. I will have to have it. It is highly detailed and the colors and markings are very attractive. I really love the detail of the 'brass' MS logo on the cowling side. Guess I'll just have to cut back elsewhere.:rolleyes2: John, and I don't know how he does it, is just getting better and better. -- Al

Hi Al,

First, you're very much welcome!:salute::

The Eindecker does have some details that are absent on ACE-18, the compass and anemometer for instance. However, the MS-N has items like the simulated brass logo that you mention. The newer model simply oozes quality of construction, as well as paint and markings. The only rationale that I can see for the difference in price is the dimensions of the models. The E.III was considerably larger, both in wingspan and length. If Wiki can be trusted in this instance, the Fokker rounded out to 31 x 24 ft, whereas the MS was about 27 x 19 ft. Those figures are the only explanation that I can offer as to the significant disparity in cost.

-Moe

Last edited:

Terp152

Major

- Joined

- Sep 17, 2009

- Messages

- 6,737

Moe, thanks for posting such great pics. I almost passed on this model but couldn't resist a great price reduction from an online dealer ($40 off retail) for a JJD piece. Your review and pics convinced me of the decision to add this acft to the collection. Expect mine to arrive by end of week. Chris

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

Moe, thanks for posting such great pics. I almost passed on this model but couldn't resist a great price reduction from an online dealer ($40 off retail) for a JJD piece. Your review and pics convinced me of the decision to add this acft to the collection. Expect mine to arrive by end of week. Chris

You're welcome, Chris. It's a great companion piece for the Eindecker. When your model arrives, let us know what you think of it "in the flesh."

-Moe

Terp152

Major

- Joined

- Sep 17, 2009

- Messages

- 6,737

I thought the Morane had metal plates bolted to the prop to deflect bullets, but the device used is actually much more sophisticated. Still, would hate to be in the pilot's seat firing thru, literally, the propeller. {eek3} This is another great acft model by JJD. The weathering is superb, especially around the wiring attachment points. Small details that set JJD apart from the competition. Wiring is better on TGM acft than the clear mono-filament used here IMO. Very plsd to add this one to my collection. Chris

ivanmoe

Command Sergeant Major

- Joined

- Feb 2, 2013

- Messages

- 2,959

I thought the Morane had metal plates bolted to the prop to deflect bullets, but the device used is actually much more sophisticated. Still, would hate to be in the pilot's seat firing thru, literally, the propeller. {eek3} This is another great acft model by JJD. The weathering is superb, especially around the wiring attachment points. Small details that set JJD apart from the competition. Wiring is better on TGM acft than the clear mono-filament used here IMO. Very plsd to add this one to my collection. Chris

Hi Chris,

Great pics. Really like the solidness of this one. With so many rigged-models, I feel as though I've got to hold my breath whenever I handle the piece. In that same vein, I've got to extend Jenkins yet another nod for durability. I own the entire KotS range, and I've never done any sort of serious damage to one of them. That's not to say that there hasn't been a mishap, or two. For instance, I had a tripe fall off of a three inch display riser onto the deck beneath it. I grimaced and examined the model for some manner of hangar-rash, only to find that it had come through the incident unscathed! For the record, I'm not suggesting that any of the faithful should try their luck at home in this regard!

I've never exchanged thoughts with JJ about the monofilament, but I have to assume that he's using the material to keep his costs down. Fishing line is inexpensive, easy to run and adjust, and can be used in extended lengths for "cats cradling." While this might not have been necessary on some of his models with less complex rigging, a model like a SPAD would be very difficult to cable-out, completely, with wire or even thread. In the way of other alternatives, I've seen everything from heated, stretched-sprue, to photo-etch and brass-rods used for simulated bracing wires. Each has strengths as a candidate for rigging a model, but all of them have an unfortunate characteristic in that each wants to "remember" the last bit of abuse that was inflicted on it, a crimp in metal wire for instance. Monofilament is MUCH more forgiving of twists and folds, and even dislocation. It has occurred to me that Jenkins would better served were it to procure and employ some of the material in a gray or silver color so as to make the true nature of "the cabling" less discernible.:wink2:

Having spent many an hour admiring Jenkins' work with the KotS models, I've developed a lot of ideas as to how they might be improved, beyond revisiting the bracing material, that is. One little addition that would do wonders for detailing the models would be some simple metal sleeves to be used as simulated turnbuckles on the bracing. JJ simulates metal parts for it's models, both metal and resin, but I believe that they are all molded. It's often occurred to me that a better method for producing parts like weapons or engine components would be machining. The results would almost certainly be fantastic, but I suspect that Jenkins would have to find yet another supplier and that the $$$ would add up, PDQ. And, hey, what about rubber-like material for the tires?

Thanks for posting your terrific pics and congrats on getting such a great deal on ACE-18!

-Moe

mestell

Colonel

- Joined

- Feb 12, 2008

- Messages

- 9,606

Excellent Chris . . . . Since I am trying to keep my JJD WWI collection to 1917-1918 Western Front time frame, I thought I would pass on the Eindecker, then Moe posted his review of it and that pushed me over the edge and I got one. I thought I would pass on the Morane but now, once again, nicely displayed photos of the Morane such as yours is changing my mind.

:smile2: Mike

:smile2: Mike

maddadicus

2nd Lieutenant

- Joined

- Feb 8, 2006

- Messages

- 3,333

I thought the Morane had metal plates bolted to the prop to deflect bullets, but the device used is actually much more sophisticated. Still, would hate to be in the pilot's seat firing thru, literally, the propeller. {eek3} This is another great acft model by JJD. The weathering is superb, especially around the wiring attachment points. Small details that set JJD apart from the competition. Wiring is better on TGM acft than the clear mono-filament used here IMO. Very plsd to add this one to my collection. Chris

You would think such an attachment would cause the propeller to spin out of balance..Michael

Not to mention the problem if the wedges weren't perfectly aligned or they shifted at all. Even with everything working correctly, the bullets hitting the wedges could still cause the propeller to shatter so it was a real hit or miss proposition and could, obviously, be just as dangerous to the shooter as the shootee. -- AlYou would think such an attachment would cause the propeller to spin out of balance..Michael

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)