You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In my spare time... (1 Viewer)

- Thread starter mikemiller1955

- Start date

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Michael . . . . I just found this thread of your . . . absolutely marvelous creations . . . . . Miller's Miniatures has a good ring to it :wink2:. Very enjoyable to view all of your projects . . .

:smile2: Mike

Mike...thanks for taking the time to leave the nice comment...

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Mike,

The roof of your latest, where did you source it from mate? it looks just perfect for French buildings and the right scale it seems.

Wayne.

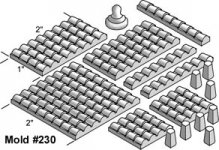

Wayne...the roof was created with a Hirst Art's mold...here is the link and some pics of some other buildings I did with it...it's easy to use...cheap and pretty nice...

Attachments

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Wayne...here is a copy of what the mold will produce per casting...I personally did not make the buildings in the 2 small pictures...they are off his website...if you want to try it and need any help or advice...send me a PM...

Attachments

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Wayne...sorry...I forgot to include the link...here it is...

http://www.hirstarts.com/molds/moldsroof.html

http://www.hirstarts.com/molds/moldsroof.html

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Wayne...they were intended for "wargamers"...in fact...all of the detailed plans from Hirst Art's website to build specific structures are for wargaming...you can disregard of of the plans as the doorways and height are much too small for the figures we collect...but I personally think they are oversized for 20-28mm figures...the scale is much better in my opinion for 54-60mm figures...I have built many structures...from castles to small buildings...do you remember the beautiful "wharf/dock" diorama by Barney Womble...that was with Hirst Arts' molds...

waynepoo

Colonel

- Joined

- Jan 3, 2012

- Messages

- 9,801

Mike,Wayne...they were intended for "wargamers"...in fact...all of the detailed plans from Hirst Art's website to build specific structures are for wargaming...you can disregard of of the plans as the doorways and height are much too small for the figures we collect...but I personally think they are oversized for 20-28mm figures...the scale is much better in my opinion for 54-60mm figures...I have built many structures...from castles to small buildings...do you remember the beautiful "wharf/dock" diorama by Barney Womble...that was with Hirst Arts' molds...

Have already placed an order for some molds and look forward to having a play with them:wink2: Tell me what did you use plaster of paris, dental stone or something else?

Cheers.

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Wayne...you need something stronger than plaster of paris...it's no good...it only has a compression strength of 2,000 PSI...it's not a good product at all if you want a brick that will last...it will crumble as it has no strength...

Hydrocal...which is a commercial plaster...is sold in most hobby stores...Hobby Lobby...Michaels...in the US...it has a compression strength of 5,000 PSI...which again...is not that good...

the dental plasters are very expensive...as it has the name "dental" is on it...I think it's priced as a specialty item...however...some are extremely strong ranging to 18,000 PSI...but very hard to find...unless you have a dentist friend...

I use and recommend Hydrostone...it has a PSI of 10,000 and makes an almost unbreakable cast...hard as stone...and dry time is about 15-20 minutes per mold...I have never had a brick chip and I have cast thousands...

the problemm is that the plasters are heavy to ship...usually sold in 20-40 pound bags...so you can imagine the shipping costs on them...

here is a link of a guy on Ebay that I buy mine from...

http://www.ebay.com/sch/plasterguys/m.html?_nkw=&_armrs=1&_ipg=&_from=

here is a link to my most recent purchase from him...

http://www.ebay.com/itm/16138082784....l2649&ssPageName=STRK:MEBIDX:IT#ht_422wt_645

his shipping is free in the US...I know that doesn't help you at all...sorry...but hopefully you can find a plaster/mortar/cement supplier in Australia where shipping won't be a financial burden...

the molds are suitable for resin if you prefer plastic...but a 2 part resin is very expensive...a 2 gallon batch being about $100 from Alumalite...one reason the resin buildings from the manufacturers are seem expensive...still...I prefer Hydrostone...

Wayne...it is fun to cast these molds...after a couple of hours...you have a pile of bricks in front of you...they seem to multiply geometrically...almost like rabbits...^&grin...you're only limited by your imagination in what you can create...

I have become friends with the guy that I buy mine from...they ship it in a plastic bag...inside a sealed box...

he told me one day...a box of it broke at the post office...they closed the post office as they thought it was anthrax...^&grin

Hydrocal...which is a commercial plaster...is sold in most hobby stores...Hobby Lobby...Michaels...in the US...it has a compression strength of 5,000 PSI...which again...is not that good...

the dental plasters are very expensive...as it has the name "dental" is on it...I think it's priced as a specialty item...however...some are extremely strong ranging to 18,000 PSI...but very hard to find...unless you have a dentist friend...

I use and recommend Hydrostone...it has a PSI of 10,000 and makes an almost unbreakable cast...hard as stone...and dry time is about 15-20 minutes per mold...I have never had a brick chip and I have cast thousands...

the problemm is that the plasters are heavy to ship...usually sold in 20-40 pound bags...so you can imagine the shipping costs on them...

here is a link of a guy on Ebay that I buy mine from...

http://www.ebay.com/sch/plasterguys/m.html?_nkw=&_armrs=1&_ipg=&_from=

here is a link to my most recent purchase from him...

http://www.ebay.com/itm/16138082784....l2649&ssPageName=STRK:MEBIDX:IT#ht_422wt_645

his shipping is free in the US...I know that doesn't help you at all...sorry...but hopefully you can find a plaster/mortar/cement supplier in Australia where shipping won't be a financial burden...

the molds are suitable for resin if you prefer plastic...but a 2 part resin is very expensive...a 2 gallon batch being about $100 from Alumalite...one reason the resin buildings from the manufacturers are seem expensive...still...I prefer Hydrostone...

Wayne...it is fun to cast these molds...after a couple of hours...you have a pile of bricks in front of you...they seem to multiply geometrically...almost like rabbits...^&grin...you're only limited by your imagination in what you can create...

I have become friends with the guy that I buy mine from...they ship it in a plastic bag...inside a sealed box...

he told me one day...a box of it broke at the post office...they closed the post office as they thought it was anthrax...^&grin

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

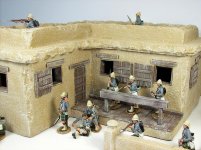

A small desert building...oops...forgot the pics...

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

villagehorse

Lieutenant General

- Joined

- Feb 5, 2010

- Messages

- 16,716

The removable roof is excellent Mike, just allows that little more versatility. Always liked these JJD figures, which were the first I collected from John. Robin.

wayne556517

Lieutenant General

- Joined

- Aug 28, 2007

- Messages

- 16,991

Superb Mike how are the sales going.

TomNT

Lieutenant Colonel

- Joined

- May 7, 2011

- Messages

- 7,986

The removable roof is excellent Mike, just allows that little more versatility. Always liked these JJD figures, which were the first I collected from John. Robin.

Superb Mike how are the sales going.

Excellent Mike and I agree with Robin's comment about the removable roof, it makes the building more versatile just like many of the K&C buildings and structures. I would also be interested in how your sales are going?

Tom

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

ty Robin...

ty Wayne...

ty Tom...

I agree...the removeable roof is the way to go...it requires a little more work on my part...but allowing the buyer to place the figures inside the building is much cooler...

I have been really fortunate on selling any and all the structures I have made…the most important thing to me is that I really enjoy building them…it’s relaxing to me to take a piece of foam and a razor…and then create something unique that works with my collecting tastes…

I really think the props and buildings enhance the shelf collection so much more than displaying the figures by themselves…

I have sold 2 very large scale forts and a couple of smaller ones…I have sold at least 50-75 smaller buildings like these…the truth is…the only piece I have ever kept was a large castle that I built…I usually take a lot of dioramas and buildings to the Texas Toy Soldier Show and sell them there…

I don’t make anything that any other Treefrogger can’t make…I think I do okay selling mine because mine are one off pieces…and not factory produced in mass quantities…mine are more unique…

In the last few months I have done exceptionally well on Ebay…however…in the last 2 weeks…I have sold almost nothing…but to me…the fun is in making them…if I can sell them…that’s a huge bonus…

ty Wayne...

ty Tom...

I agree...the removeable roof is the way to go...it requires a little more work on my part...but allowing the buyer to place the figures inside the building is much cooler...

I have been really fortunate on selling any and all the structures I have made…the most important thing to me is that I really enjoy building them…it’s relaxing to me to take a piece of foam and a razor…and then create something unique that works with my collecting tastes…

I really think the props and buildings enhance the shelf collection so much more than displaying the figures by themselves…

I have sold 2 very large scale forts and a couple of smaller ones…I have sold at least 50-75 smaller buildings like these…the truth is…the only piece I have ever kept was a large castle that I built…I usually take a lot of dioramas and buildings to the Texas Toy Soldier Show and sell them there…

I don’t make anything that any other Treefrogger can’t make…I think I do okay selling mine because mine are one off pieces…and not factory produced in mass quantities…mine are more unique…

In the last few months I have done exceptionally well on Ebay…however…in the last 2 weeks…I have sold almost nothing…but to me…the fun is in making them…if I can sell them…that’s a huge bonus…

29 Let's Go

Sergeant Major

- Joined

- Mar 13, 2011

- Messages

- 1,886

Mike,

You have a nice village going on there. Great work with your doors and windows, it's what makes the buildings pop.

Steve

You have a nice village going on there. Great work with your doors and windows, it's what makes the buildings pop.

Steve

waynepoo

Colonel

- Joined

- Jan 3, 2012

- Messages

- 9,801

Mike,Wayne...you need something stronger than plaster of paris...it's no good...it only has a compression strength of 2,000 PSI...it's not a good product at all if you want a brick that will last...it will crumble as it has no strength...

Hydrocal...which is a commercial plaster...is sold in most hobby stores...Hobby Lobby...Michaels...in the US...it has a compression strength of 5,000 PSI...which again...is not that good...

the dental plasters are very expensive...as it has the name "dental" is on it...I think it's priced as a specialty item...however...some are extremely strong ranging to 18,000 PSI...but very hard to find...unless you have a dentist friend...

I use and recommend Hydrostone...it has a PSI of 10,000 and makes an almost unbreakable cast...hard as stone...and dry time is about 15-20 minutes per mold...I have never had a brick chip and I have cast thousands...

the problemm is that the plasters are heavy to ship...usually sold in 20-40 pound bags...so you can imagine the shipping costs on them...

here is a link of a guy on Ebay that I buy mine from...

http://www.ebay.com/sch/plasterguys/m.html?_nkw=&_armrs=1&_ipg=&_from=

here is a link to my most recent purchase from him...

http://www.ebay.com/itm/16138082784....l2649&ssPageName=STRK:MEBIDX:IT#ht_422wt_645

his shipping is free in the US...I know that doesn't help you at all...sorry...but hopefully you can find a plaster/mortar/cement supplier in Australia where shipping won't be a financial burden...

the molds are suitable for resin if you prefer plastic...but a 2 part resin is very expensive...a 2 gallon batch being about $100 from Alumalite...one reason the resin buildings from the manufacturers are seem expensive...still...I prefer Hydrostone...

Wayne...it is fun to cast these molds...after a couple of hours...you have a pile of bricks in front of you...they seem to multiply geometrically...almost like rabbits...^&grin...you're only limited by your imagination in what you can create...

I have become friends with the guy that I buy mine from...they ship it in a plastic bag...inside a sealed box...

he told me one day...a box of it broke at the post office...they closed the post office as they thought it was anthrax...^&grin

I was going to send you a PM but maybe some fellow members may also be interested in the answers to the questions I wish to ask you. I have some 'Hirst' moulds on the way and therefore took

your advise and got some 'Hydrostone' and so I would like to tap into your experience of using the same moulds with the same casting agent. First...what ratio of Hydrostone to water mix did you fine best. Second... what measuring system did you fine that worked best for making the mix. Any suggestions and or tips you may like to offer would be greatly appreciated.

Thanks in advance mate.

Wayne.

mikemiller1955

Lieutenant General

- Joined

- Aug 3, 2008

- Messages

- 17,677

Mike,

I was going to send you a PM but maybe some fellow members may also be interested in the answers to the questions I wish to ask you. I have some 'Hirst' moulds on the way and therefore took

your advise and got some 'Hydrostone' and so I would like to tap into your experience of using the same moulds with the same casting agent. First...what ratio of Hydrostone to water mix did you fine best. Second... what measuring system did you fine that worked best for making the mix. Any suggestions and or tips you may like to offer would be greatly appreciated.

Thanks in advance mate.

Wayne.

Wayne...

honestly...I never once used a measuring ratio and I have cast 1,000's of bricks...^&grin...for real...

almost any consistency will work...but I try to make something like a thin pancake batter...

the thicker it is...the quicker it dries...

the thicker it is...the harder it dries too...

but if it's too thick...you may see air bubbles that couldn't escape...they really look bad too...

Bruce Hirst has a method to eliminate trapped bubbles with an elaborate vibrating table set up...you really don't need that...

before I pour the mold...I spritz it with a water solution and then shake off the excess water...the water solution has a squirt of dishawasher rinse agent in it...you know...the blue stuff...over here it's called "rinse aid"...and it's supposed to help the batter seep into all the cracks...after I pour the mold...I tap if pretty hard with my putty knife which allows the bubbles to rise to the surface and escape...

I use a 12oz plastic cup...a large squirt bottle of water and a wooden tongue depressor to mix it...

some molds are deeper than others and require more batter...but you will get the hang of it after a couple of batches...the tile roof mold is very thin and uses very little Hydrostone...

I try not to waste any...so if I pour a mold and have 1-2 ounces left over...I get another mold and pour some select spots in that mold of bricks that I use frequently...

I do mine over a piece of newspaper...it makes a mess...after 2-3 casts...you will change the newspaper...

it usually takes 15-20 minutes to cure...but a fan on it speeds that up...

I pour my mold...let it sit for 2-3 minutes...the water comes to the top as the Hydrostone settles...then I scrape off the excess...

then wait 15 minutes to check it to make sure it's hard before taking out...

Wayne...I have seen the quality of your work...you're an accomplished modeler...this will be easy for you...you will be in expert after 6 casts...you will be amazed how your pile of bricks grows so quickly...

one last tip...

get some quality plastic baggies...make sure to label them with the molds #...with a marker...

ex: #70...#250...etc...

put all finished pieces of each finished cast into to that bag so you can find them easily when you want them...once they get mixed up...it's difficult to sort them out...

you will thank me for that tip later...^&grin

dying to see your work...they are addictive...good luck...

my favorite mold right now is #75...the "ruined fieldstone mold"...it works so good for exposed damaged brick...look at some of the "collapsed roof buildings I did...that is a nice mold...

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)